Personnel Sanitizing Tunnel

Personnel Sanitizing Tunnel

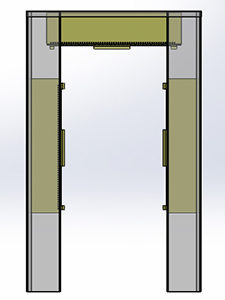

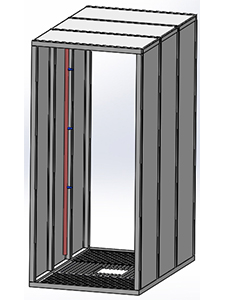

Emax Sanitizing Tunnel is installed at the entry side of the main gate area to facilitate easy sanitizing of personnel & visitors at the time of entry. The sanitizing tunnel helps contain the Viruses and Contaminants that are over the clothes and external wear of the Personnel entering the Premises.

In this tunnel the Sanitizing is done in an enclosure, by mist spraying the sanitizing solution through especially designed mist spray nozzles working on the principle of atomisation of solution into very fine mist using high pressure pump. The Personnel are recommended to wear the masks and cover or close their eyes to prevent mist entering eyes nose and ears. An optional Air Blow Tunnel at exit will help blow off excess droplets if any present over clothing.

The Sanitizer solution tank is provided with a dosing pump which will dose the required quantity of sanitizer solution each time the tank is filled with fresh water. The system operates automatically as a person enters the Tunnel and the spray starts, it stops after a pre-set time of spraying after a person has entered the Tunnel. A base tank is provided to collect the overspray drippings and can be connected to drain or emptied periodically.

The System is supplied in assembled condition and can be plugged in after making necessary connections easily at the given location.

Order Request FormTech Specs

| Walk Through Opening | 1100mm(w) X 2200 mm(h) |

| Base grating for Personnel | 1000mm (w) X 1600mm(l) |

| Base Collection tank | 40 ltrs, drain outlet 1” Bsp |

| Power supply | 440v 3PH 50 Hz |

| Sanitizing Pump | 0.5 hp, 10 Lpm |

| Dosing Pump | 6 Lph, PP |

| Sanitizing Nozzles | Misting type |

| Sanitizing Solution Tank | 40 Ltrs |

| Tunnel MOC | SS 304 |

| Air Blow Tunnel | (optional) |

| Control Panel | With automatic control, timer, emergency stop |

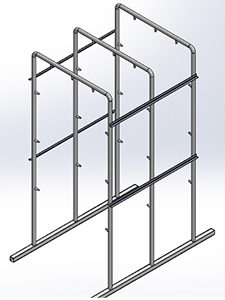

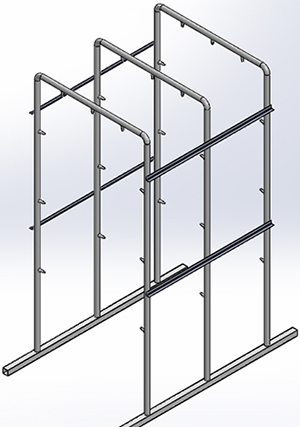

Personnel Sanitizing Walkway

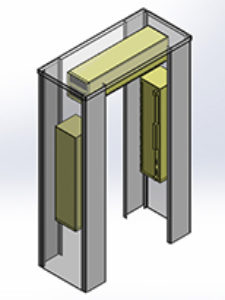

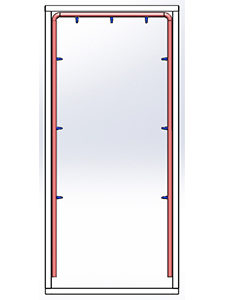

Emax Sanitizing Walkway is installed at the entry side of the main gate area to facilitate easy sanitizing of personnel at the time of entry to work places. The walk through the sanitizing walkway helps contain the Viruses and Contaminants that are over the clothes and external wear of the Personnel entering the Premises.

Emax Sanitizing Walkway is installed at the entry side of the main gate area to facilitate easy sanitizing of personnel at the time of entry to work places. The walk through the sanitizing walkway helps contain the Viruses and Contaminants that are over the clothes and external wear of the Personnel entering the Premises.

The Sanitizing is done by mist spraying the sanitizing solution through especially designed mist spray nozzles working on the principle of atomisation of solution into very fine mist using high pressure pump. The Personnel are recommended to wear the masks and cover or close their eyes to prevent mist entering eyes nose and ears. Blowers at the exit make sure that the overspray is blown off.

The Sanitizer solution tank is provided with a dosing pump which will dose the required quantity of sanitizer solution each time the tank is filled with fresh water. The system operates automatically as a person enters the walkway and the spray starts, it stops after a preset time of spraying after a person has entered the walkway.

The System is supplied in knockdown condition and can be assembled easily at the given location.

Order Request FormTech Specs:

| Walk Through Opening | 1100mm(w) X 2200 mm(h) X 2400(l) |

| Power supply | 440v 3PH 50 Hz |

| Sanitizing Pump | 0.5 hp, 15 Lpm |

| Dosing Pump | 6 Lph, PP |

| Sanitizing Nozzles | Misting type |

| Sanitizing Solution Tank | 40 Ltrs |

| Air Blow Tunnel | ( Optional) |

| Control Panel | With automatic control, timer, emergency stop |

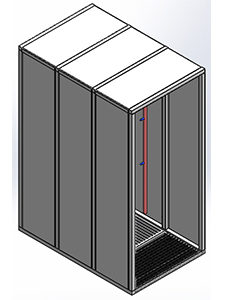

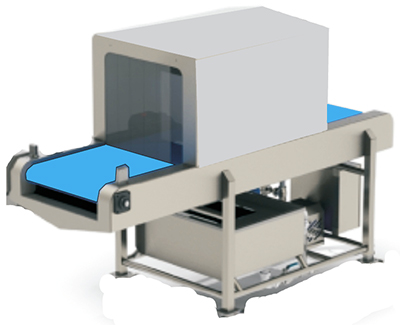

Sanitizing Conveyor

Emax Sanitizing Conveyor Tunnel is designed to reduce workplace risk of contaminants and enhance safety. Every day, packaged ingredients stored in containers, buckets, packed meats, and bags are brought into plants on delivery trucks, and could have been exposed to contaminants or viruses.

The Sanitizing Conveyor Tunnel is installed at inward inventory location, The container or bag is placed on the conveyor belt, where it is conveyed through the machine and diluted sanitizing solution is sprayed , helping to eliminate bacteria or viruses.

The solution is constantly re-circulated through filters and back into the tank. The belt is variable speed, allowing for adjustment. A photo-electric sensor positioned at the end of the tunnel will stop the conveyor if a product has not been removed, preventing it from falling on the floor.

The Sanitizing Conveyor Tunnel is fitted with a blow off system for drying excess solution.

Tech Specs:

| Envelope Size | 500mm(w) X 400 mm(h) |

| Conveyor speed | 1-3 mtrs/ min ( variable) |

| Conveyor Drive | Frequency Inverter Controlled |

| Power supply | 440v 3PH 50 Hz |

| Sanitizing Pump | 0.5 hp, 10 Lpm |

| Dosing Pump | 6 Lph, PP |

| Tunnel MOC | SS 304 |

| Filter | SS wiremesh type |

| Sanitizing Nozzles | Misting type |

| Sanitizing Solution Tank | 40 Ltrs |

| Control Panel | With automatic control, timer, emergency stop |